5 Friendly steps to choosing the perfect Vikan tools (and why it matters!)

Are you tired of cleaning confusion in your facility?

In bustling environments like food production, healthcare, or hospitality, a misplaced cleaning brush isn’t just untidy—it can be a serious risk. That’s where Vikan’s revolutionary color-coding system comes in! It’s not just about aesthetics; it’s about compliance, safety, and making your daily operations smoother than ever.

But with so many vibrant colors and specialized tools, how do you know where to start? Don’t worry, we’re here to make it simple, friendly, and totally stress-free. Let’s dive into our 5 easy steps to help you choose the perfect Vikan color-coding system for your business and unlock a new level of hygienic efficiency!

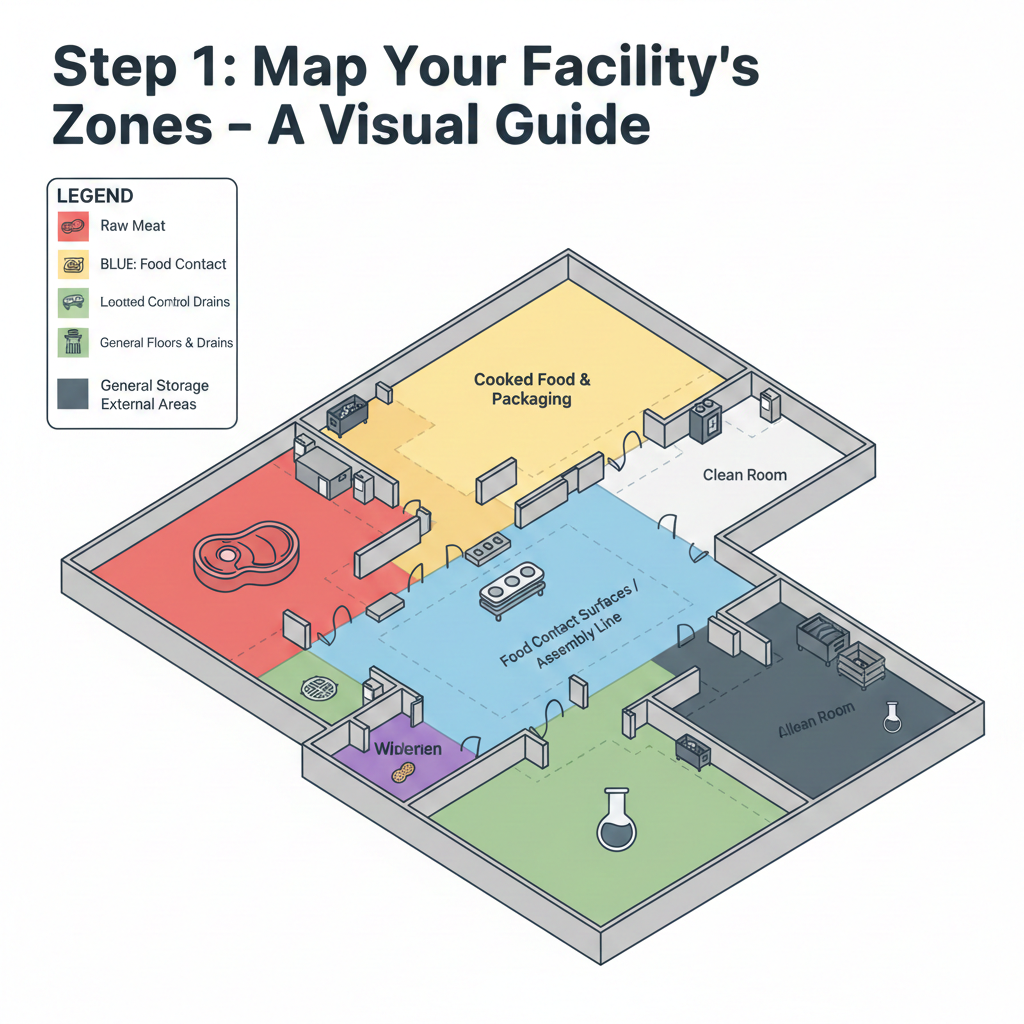

Step 1: Map Out Your “Zones” – Define Your Facility’s Areas

Imagine your facility as a chessboard, with each square having a specific purpose. Before you pick a single Vikan brush, you need to clearly define these unique areas, or “zones,” in your workspace. This is the foundational step that prevents cross-contamination and streamlines your cleaning protocols.

Think about these crucial questions:

-

Where do you handle raw ingredients versus cooked products? (e.g., Raw Meat Prep vs. Bakery Finishing)

-

Which areas come into direct contact with food or sensitive products? (e.g., Production Lines vs. General Storage)

-

What about high-risk areas like drains, waste disposal, or external zones? (These need their own segregation!)

-

Do you have specific allergen control zones? (e.g., Gluten-Free Production, Nut-Free Area)

Why this matters for your business?

Clear zone definition is the bedrock of HACCP compliance and BRCGS standards. It minimizes the risk of pathogens spreading from a low-risk area (like a floor) to a high-risk area (like a food contact surface). This proactive approach protects your brand reputation, prevents costly recalls, and ensures consumer safety.

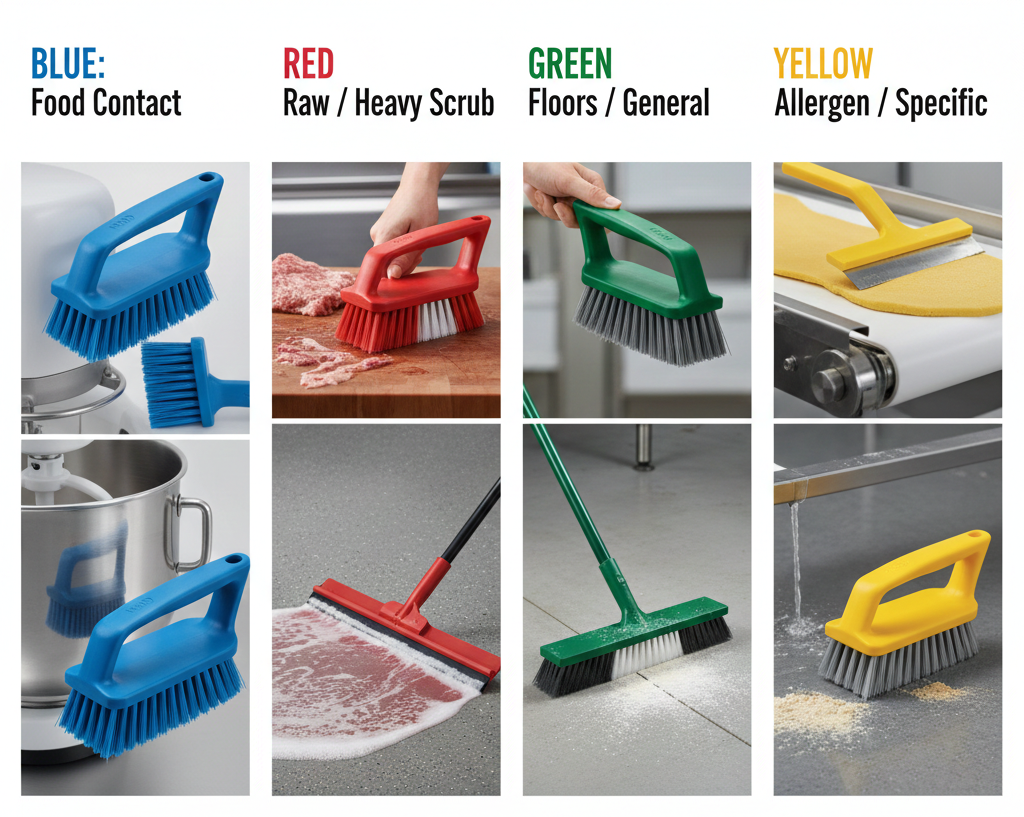

Step 2: Pick Your “Hero” Colors – Assigning Colors to Your Zones

Once your zones are clearly defined, it’s time for the vibrant part: assigning a unique color to each area! This isn’t just about making things look pretty; it’s about creating an intuitive, visual language that your entire team can understand at a glance.

Industry Standard Color Assignments (and why they’re brilliant):

-

Blue: The undisputed hero for food contact surfaces. Why? Blue is rarely found naturally in food, making any stray bristle easily visible.

-

Red: Universally recognized as a warning color, Red is perfect for high-risk areas like raw meat processing to signify “danger” and ensure strict segregation.

-

Green: Often designated for floors, general cleaning, and drains, keeping floor contaminants away from food preparation areas.

-

Yellow: Ideal for cooked food areas or allergen control for specific ingredients, providing clear separation from raw materials.

-

White: Frequently used in clean rooms or pharmaceutical environments where absolute sterility is paramount, as dirt shows up immediately.

-

Black: Best for heavy-duty, non-food contact areas like outdoor spaces, machinery, or very greasy zones.

-

Purple/Orange: Excellent for specific allergen control where dedicated tools are critical (e.g., a “Nut-Free” zone with purple tools).

Why this matters for your business?

A well-implemented color-coding system acts as a silent supervisor, guiding your staff to use the right tool in the right place, every single time. This reduces human error, speeds up training for new employees, and drastically lowers your risk profile.

Step 3: Match the Tool to the Task – Choosing the Right Vikan Product

Now that you know where to clean and what color to use, it’s time to select the perfect Vikan cleaning tool for each specific job. Vikan isn’t just about color; it’s about innovative design and superior hygiene performance. Choosing the right tool makes cleaning more effective, efficient, and ultimately, safer.

Consider these tool characteristics:

-

Bristle Stiffness:

-

Soft Bristles: Ideal for sweeping fine, dry debris like flour, sugar, or dust without scattering it.

-

Medium/Stiff Bristles: Perfect for scrubbing stubborn, dried-on grime, fats, or heavy dirt on floors and equipment.

-

Ultra Safe Technology (UST) Bristles: Vikan’s pinnacle of hygiene. These bristles are molded directly into the brush head, virtually eliminating the risk of bristle loss—a must-have for high-risk food contact areas.

-

-

Tool Type:

-

Brooms & Sweepers: For large floor areas.

-

Hand Brushes & Detail Brushes: For specific equipment, crevices, and hard-to-reach spots where biofilms love to hide.

-

Squeegees: Essential for quickly and hygienically removing liquids from floors, walls, and surfaces. Look for Vikan’s single-blade hygienic squeegees for the ultimate solution.

-

Scrapers: For tough, baked-on or frozen residue that brushes can’t tackle.

-

Waterfed Brushes: Connect directly to a hose for powerful, continuous rinsing and scrubbing.

-

Why this matters for your business?

Using the correct tool ensures thorough cleaning, reduces effort for your staff, and extends the lifespan of your equipment. It’s an investment in efficiency and optimal hygiene.

Step 4: Give Your Tools a “Home” – Storage & Organization

Congratulations! You’ve defined your zones, assigned your colors, and selected your perfect Vikan tools. But the system only works if tools are stored correctly and returned to their designated zones after use. This is where smart storage solutions come into play.

- Vikan Shadow Boards: These are incredibly effective! A shadow board displays an outline of each tool, making it immediately obvious if a tool is missing or if the wrong color tool is placed in the wrong area. They promote accountability and ensure tools are clean and ready for their next task.

- Color-Matched Wall Brackets/Hangers: Simple yet effective, these ensure that a blue brush always hangs on a blue hook, reinforcing the color code visually.

- Dedicated Storage Carts: For mobile cleaning tasks, ensure your carts are also color-coded or clearly designated for specific zones.

Why this matters for your business?

Proper storage prevents tools from being left on floors (a major cross-contamination risk!), extends their lifespan, and ensures they are easy to find. An organized cleaning station speaks volumes about your commitment to hygiene and efficiency during audits. It’s a quick win for “5S” principles!

Step 5: Expert Guidance & Continuous Improvement

The secret to a truly “audit-proof” facility is never having to guess. Even with the best tools, unique floor plans and complex production lines can raise questions. This is where professional solutioning makes the difference.

-

Audit Readiness: Ensure your color-coding plan stands up to the strictest GFSI or HACCP inspections.

-

The “Right Tool” Guarantee: Sometimes you need a specific tube brush or a high-heat scraper you didn’t know existed.

-

Ongoing Support: As your business grows and your zones change, your cleaning system should evolve with you.

Why Sunrank is Your Ultimate Vikan Partner?

Choosing a cleaning tool is easy; building a comprehensive hygiene strategy is where we excel. At Sunrank, we don’t just sell brushes, we provide peace of mind. As authorized Vikan specialists, we understand the high stakes of food safety and industrial hygiene.

When you partner with Sunrank, you gain more than a supplier; you receive a dedicated consultant focused on minimizing your cross-contamination risks and reducing your long-term equipment costs. Our Vikan solutions are designed to be durable, ergonomic, and 100% compliant with international food safety standards. Don’t leave your next audit to chance, let the experts help you shine.

Ready to Revolutionize Your Cleaning Standards?

Stop guessing and start cleaning with confidence! Whether you need a full facility color-mapping consultation or just need to restock your high-performance UST brushes, Sunrank is here to help.

Our expert team is standing by to provide custom Vikan solutioning tailored to your facility.