Food & Beverages Processing

Your trusted partner in

food and beverage processing

We know the many different hazards you must control in your diverse food and beverage production environments and can support you in maintaining those environments in a way that protects your products and your business.

Dairy Processing

Bakery Processing

Meat Processing

Confectionary Processing

Chilled, Ready-to-Eat Processing

Dry, Ready-to-Eat Processing

Suggested Products for the Food & Beverage industry

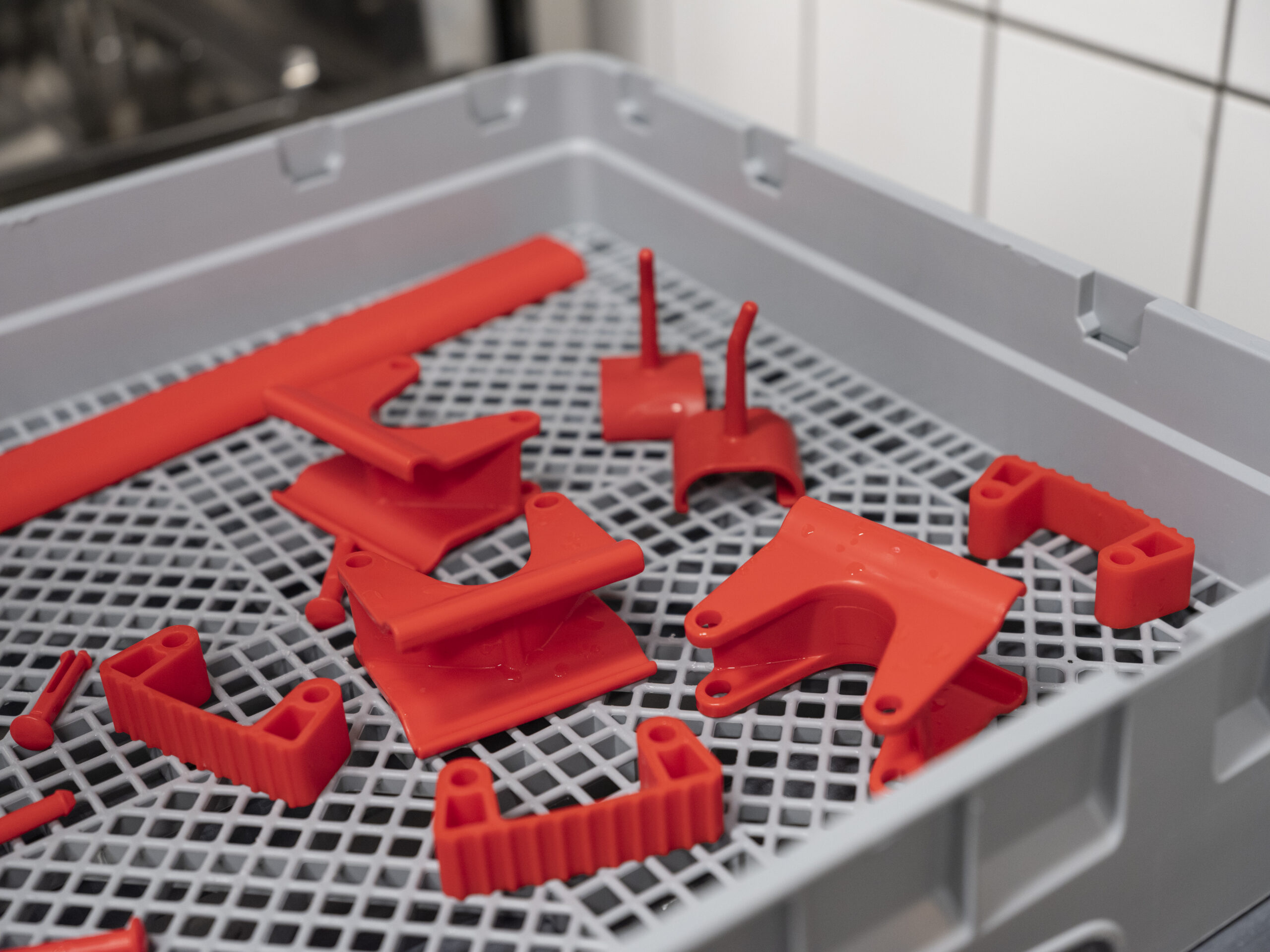

The food and beverage sector requires strict adherence to sanitation rules and regulations. Tools from Vikan are made out of tough, compliant materials such as polypropylene and stainless steel. Unlike foamed plastic or wooden tools, our high-quality products have smooth surfaces for easy clean-up and better hygiene.

Our tools are hygienically designed, which makes them easier to clean and less likely to harbor bacteria.

Vikan tools come in up to twelve colours, making them ideal for integration with colour coding plans. Colour coding helps prevent cross-contamination between raw and finished products, as well as keeping allergens separated.

Regardless of your operation’s size and complexity, Vikan has the tools and expertise to help you execute your colour coding plans.

From milking to manufacture

Vikan are here to help

We know that most dairy products fall into the chilled, ‘Ready-to-eat’ (RTE) product category. They also included dry milk powder production, used as an ingredient in many other products, and as a base for infant formula.

Microbiologically, chilled RTE products and infant formula production are classed as high-risk. Consequently, producers of these products in particular need to maintain high levels of hygiene to ensure consumer safety, longer product shelf-life, and brand reputation.

Suggested Products for Dairy processing plants

The dairy sector requires strict adherence to sanitation rules and regulations. Tools from Vikan are made out of tough, compliant materials such as polypropylene and stainless steel. Unlike foamed plastic or wooden tools, our high-quality products have smooth surfaces for easy clean-up and better hygiene.

Our tools are hygienically designed, which makes them easier to clean and less likely to harbor bacteria.

Vikan tools come in up to twelve colours, making them ideal for integration with colour-coded plans. Colour-coding helps prevent cross-contamination between raw and finished products, as well as keeping allergens separated.

Regardless of your operation’s size and complexity, Vikan has the tools and expertise to help you execute your colour-coding plans.

Bakery Processing

From milling to manufacture Vikan are here to help

Bread has been a staple in the human diet since prehistoric times. Now the range of commercial baked goods available to the consumer has greatly increased, and so have your hygiene and food safety challenges. A bakery may produce everyday mainstays, like bread, or creative new inventions that drive impulse purchases, or both. In any case the maintenance of safe, quality product will be a priority for your business.

Vegan and gluten-free bakery options have been some of the most successful launched over the last few years. If these products are made alongside more traditional baked goods, strict control of ingredients may be required to minimise the risk of product cross-contamination, in compliance with legal and labelling requirements.

Suggested Products for Bakeries

The bakery sector requires strict adherence to sanitation rules and regulations. Tools from Vikan are made out of tough, compliant materials such as polypropylene and stainless steel. Unlike foamed plastic or wooden tools, our high-quality products have smooth surfaces for easy clean-up and better hygiene.

Our tools are hygienically designed, which makes them easier to clean and less likely to harbor bacteria.

From cutting room to cooking Vikan are here to support

We know that the hygiene and food safety challenges you face in meat processing vary, dependent on whether you process raw meats, e.g., meat cuts, minced meat, mechanically separated meat (MSM); frozen meats or cooked meats; and the types of meat processed (red meats, poultry, game etc). From control of microbial hazards to minimising the risk of product contamination with other meat species, Vikan’s tools and experts are here to help.

All these challenges present a risk to food quality, and many to food safety, both can lead to loss of business and damage to brand reputation. Fortunately, the risks they pose, to both consumers and businesses, can be significantly reduced through the appropriate selection, use, and maintenance of manual cleaning equipment.

Suggested Products for Meat processing plants

The meat sector requires strict adherence to sanitation rules and regulations. Tools from Vikan are made out of tough, compliant materials such as polypropylene and stainless steel. Unlike foamed plastic or wooden tools, our high-quality products have smooth surfaces for easy clean-up and better hygiene.

Our tools are hygienically designed, which makes them easier to clean and less likely to harbor bacteria.

Vikan tools come in up to twelve colours, making them ideal for integration with colour-coded plans. Colour-coding helps prevent cross-contamination between raw and finished products, as well as keeping allergens separated.

Regardless of your operation’s size and complexity, Vikan has the tools and expertise to help you execute your colour-coding plans.

Chocolate, candies, confections of all sorts

Chocolate, candies, jellies, gums, sherbets, sweets, toffees, fudge, and liquorice (a Danish favorite!) – whatever sweet treats you manufacture we know that maintaining the quality and safety of your products is key.

We also know that cleaning in a confectionary manufacturing site presents some unique challenges, and that’s where Vikan can help. We support some of the world’s largest confectionary manufactures by providing products and advice tailored to their needs.

Suggested Products for Confectionary processing

The confectionary sector requires strict adherence to sanitation rules and regulations. Tools from Vikan are made out of tough, compliant materials such as polypropylene and stainless steel. Unlike foamed plastic or wooden tools, our high-quality products have smooth surfaces for easy clean-up and better hygiene.

Our tools are hygienically designed, which makes them easier to clean and less likely to harbor bacteria.

Vikan tools come in up to twelve colours, making them ideal for integration with colour-coded plans. Colour-coding helps prevent cross-contamination between raw and finished products, as well as keeping allergens separated.

Regardless of your operation’s size and complexity, Vikan has the tools and expertise to help you execute your colour-coding plans.

One of the most challenging in the food industry

With our microbiological expertise and extensive range of control options, let Vikan help you put the ‘chill’ back into your chilled food production.

Chilled Ready-To-Eat (RTE) foods are foods that will not be cooked or reheated before serving.

They include salads (containing fruit, vegetables, beans, sprouts, pulses, grains, egg, pasta etc.), cooked and cured meats, smoked fish, sushi, chilled desserts, sandwiches, cheese, and food that has been cooked in advance to serve cold. All require the highest standards of hygienic production to ensure maximum shelf-life and consumer safety.

Suggested Products for Chilled RTE Product Processing

Chilled RTE Product Processing requires strict adherence to sanitation rules and regulations. Tools from Vikan are made out of tough, compliant materials such as polypropylene and stainless steel. Unlike foamed plastic or wooden tools, our high-quality products have smooth surfaces for easy clean-up and better hygiene.

Our tools are hygienically designed, which makes them easier to clean and less likely to harbor bacteria.

Our tools are hygienically designed, which makes them easier to clean and less likely to harbor bacteria.

Vikan tools come in up to twelve colours, making them ideal for integration with colour-coded plans. Colour-coding helps prevent cross-contamination between raw and finished products, as well as keeping allergens separated.

Regardless of your operation’s size and complexity, Vikan has the tools and expertise to help you execute your colour-coding plans.

Snacking is on the rise! Boost your business with support from Vikan

The global snack food market was valued at 427.02 Billion USD in 2020 and is projected to grow significantly over the next 5 years. Dry and low moisture snacks, like crisps (or chips), cereal bars, and dried fruit are popular and convenient snacks in many parts of the world. Maintaining the quality and integrity of these products is key to ensuring consumer satisfaction and safety and that’s where Vikan can help.

Whether your dry snacks are sweet or savoury, maintaining them at optimum quality requires careful control of moisture throughout production. Excess moisture in the production environment can lead to poor product quality, spoilage, and waste.

Suggested Products for Dry Snacks Processing

Dry snacks processing requires strict adherence to sanitation rules and regulations. Tools from Vikan are made out of tough, compliant materials such as polypropylene and stainless steel. Unlike foamed plastic or wooden tools, our high-quality products have smooth surfaces for easy clean-up and better hygiene.

Our tools are hygienically designed, which makes them easier to clean and less likely to harbor bacteria.

Vikan tools come in up to twelve colours, making them ideal for integration with colour-coded plans. Colour-coding helps prevent cross-contamination between raw and finished products, as well as keeping allergens separated.

Regardless of your operation’s size and complexity, Vikan has the tools and expertise to help you execute your colour-coding plans.